TSA backs calls for research into textiles and infection control; ‘PHE should revise 2007 guidelines’

The Textile Services Association (TSA) is backing urgent calls for research into the ability of infectious diseases, including COVID-19, to survive on linen and clothing, even after it is washed in a domestic setting. It’s especially concerning because many nurses and care home workers wash their uniforms at home – and there is evidence that some infection outbreaks in healthcare settings have been caused by inadequately managed washing equipment. The TSA is also calling for Public Health England to revise guidelines the Association believes are outdated.

Currently Public Health England recommends uniforms are washed in commercial laundries, but it is not compulsory. Furthermore, it says that domestic washing should be adequate. However, this is based on reviews published in 2007 – and experts are saying that, especially in the light of the COVID-19 pandemic, it’s high time for proper research that will give accurate guidance on the matter. There is also increasing consensus within the research community that the infrastructure, processes and quality standards in a commercial laundry mean they are much better equipped to deal with all the risks associated with infectious textiles than is possible in a household or on-premises laundry setting.

“It can’t be right to base guidance on reviews that were done 13 years ago,” says David Stevens, CEO of the Textile Services Association. The TSA is currently conducting a survey of care home owners to find out about their current practices. The Association is also working with the DHSC, who have agreed to review the infection control procedures around laundry. “They have said they would welcome a revised guidance document that can be issued to the care home sector,” says Stevens.

“When it comes to best practice for health workers who are laundering their uniforms at home, the PHE guidance is onerous,” Stevens adds. “It says that workers should transport the uniform in a disposable plastic bag, and wash at the highest temperature it can tolerate, in a separate half load, and it should be ironed or tumble dried. It’s a lot to ask of a tired worker just home from a stressful shift.”

Previous research by Dr Katie Laird of De Montfort University (DMU) found that healthcare workers were not always adhering to these policies when laundering at home, underlining the risk of inadequate decontamination. It showed 44% of workers were laundering their uniforms at temperatures below 60°C, and 40% laundered them with other clothing items.

The most recent paper on the subject was published in August 2020 by Dr Laird and her colleague, Dr Lucy Owen from the Infectious Disease Research Group at DMU. They point out the need for even more rigorous infection control, following the emergence of COVID-19, and underline the lack of empirical research into the role of textiles as potential fomites (infection carriers) in healthcare environments. Furthermore, they reference a number of studies that indicate that microorganisms can survive on textiles for extended periods of time, and case studies that link outbreaks with inadequate washing processes and infrastructure in on-premise healthcare settings. This is important because it underlines the infection control benefits of the measures taken in a commercial laundry, compared to those in a domestic or on-premise setting.

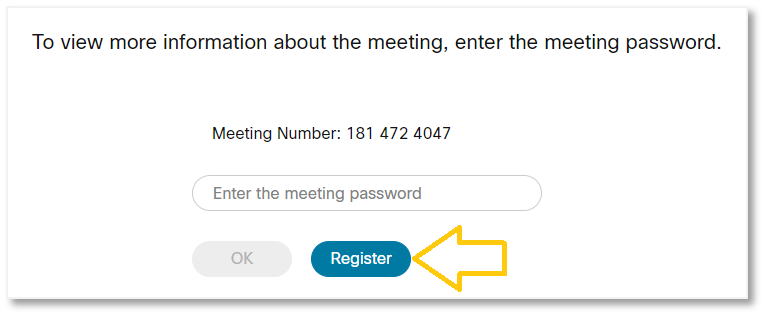

The article, called The role of textiles as fomites in the healthcare environment: a review of the infection control risk, is available to download here.

“Given what the experts are saying, surely we should be erring on the side of caution and ensuring that healthcare workers’ uniforms are washed in commercial laundries, with the appropriate hygiene certification,” says Stevens. “We will be lobbying the government and PHE to fund research to establish the facts, or at the very least to revise the current guidelines.”

If you wish to discuss the above or if you would like any further information, please do not hesitate to contact us on 020 3151 5600 or at tsa@tsa-uk.org.